|

INTRODUCTION

In 2008 the Vought Aircraft Heritage Foundation (VAHF) selected the Vought O3U-3 aircraft as a build-from-scratch fabrication project. Vought would fabricate a replica of one of the Chance Vought Aircraft Company's outstanding products of its early years: the 1932 O3U-3 Corsair I float plane. This is a second replica which will join the other replica (VE-7 Bluebird) plus nine restored Vought aircraft in famous air museums in the U.S.

Fabrication started in 2009 and is estimated to be completed in 2021. Fabrication has been delayed by two work shutdowns due to loss of hanger facilities. There was an 18 month work shutdown in 2014-2016 and a 9 month shutdown May, 2018 to February, 2019. Work has now resumed in a building facility made available by the Grand Prairie Independent School District.

SUMMARY

Background

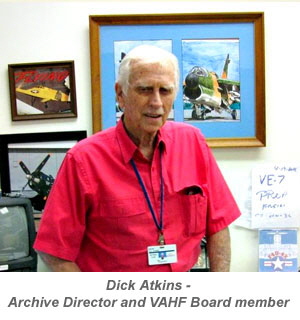

Selection of the O3U-3 Corsair as our next VAHF retiree project began in an unusual fashion. In early 2008 Dick Atkins, VAHF Archive Director, was asked to take our senior member, 97 year old Teddy Trept, to the International Plastic Modelers Society (IPMS) aircraft model display in Dallas, Texas. Dick and Teddy immediately spotted a beautiful model of the O3U-3, US Navy Serial Number (SN) 9156. This model was destined to be a donation to the National Museum of Naval Aviation in Pensacola, Florida. In addition, the actual fuselage side fabric of O3U-3 SN 9156 was also donated to the museum. Selection of the O3U-3 Corsair as our next VAHF retiree project began in an unusual fashion. In early 2008 Dick Atkins, VAHF Archive Director, was asked to take our senior member, 97 year old Teddy Trept, to the International Plastic Modelers Society (IPMS) aircraft model display in Dallas, Texas. Dick and Teddy immediately spotted a beautiful model of the O3U-3, US Navy Serial Number (SN) 9156. This model was destined to be a donation to the National Museum of Naval Aviation in Pensacola, Florida. In addition, the actual fuselage side fabric of O3U-3 SN 9156 was also donated to the museum.

Atkins reasoned that this aircraft would be the perfect next project, since the Navy Museum has a replica of the first Vought Navy aircraft, the VE-7 Bluebird, and a Vought SB2U-1 dive bomber. The glory years of the "Eyes of the Fleet" provided by Vought Corsairs was not represented. Dick Atkins made a presentation to VAHF management and craftsmen in mid-2008 recommending that they build the O3U-3. The recommendation was approved and the project began. Atkins reasoned that this aircraft would be the perfect next project, since the Navy Museum has a replica of the first Vought Navy aircraft, the VE-7 Bluebird, and a Vought SB2U-1 dive bomber. The glory years of the "Eyes of the Fleet" provided by Vought Corsairs was not represented. Dick Atkins made a presentation to VAHF management and craftsmen in mid-2008 recommending that they build the O3U-3. The recommendation was approved and the project began.

Project Objectives

The primary objective of this project was to produce a replica of the O3U-3 Corsair with external appearance and cockpit internal appearance as defined by the production drawings.

Deviations may be taken where it was practical to use other means and where the deviation was not externally visible.

The replica is to be delivered on floats with a stand for movement.

O3U-3 CORSAIR DESCRIPTION

O3U-3 Navy Mission

The O3U-3 performed the patrol and observation mission for Navy ship task forces at sea. Before the days of RADAR, patrol aircraft were sent out from battleships and cruisers to look "over the horizon" for enemy ships. Information such as number and type of ships, their location and sailing direction were transmitted by radio back to the task force.

The aircraft were catapulted from a ship deck. After completing their mission the aircraft would land next to the ship and then be hoisted back onto the deck by crane. In the case of S/N 9156 (The O3U-3 model depicted in the Summary) it stationed aboard was the Battleship, Pennsylvania.

O3U-3 Physical Description

The Corsair was a two-place biplane. It was defensively armed with a forward firing 30 caliber machine gun for the pilot and an aft facing flexible 30 caliber machine gun for the co-pilot/observer. The aircraft was equipped with bomb racks on each lower wing.

O3U Designations and Quantities

The O3U-3 made its first flight in 1932, and 76 aircraft were produced. All versions of the O3U aircraft fabricated between 1930 and 1934 totaled 309 airframes.

The O3U series of aircraft are described in detail at: O3U Products

DESIGN ENGINEERING

Search for Drawings

In 2008, the Vought Aircraft Heritage Foundation had a large archive of Vought heritage drawings, mostly in the form of microfilm reels. The archives included most Vought aircraft from the 1920s through the 1960s A-7, and did include the O3U-3.

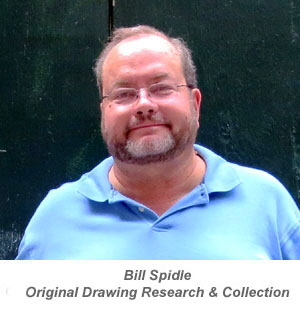

Volunteer archivist Bill Spidle agreed to do the research and find the drawings necessary to build the airplane. Bill gathered 1,600 + drawings from the VAHF microfilm library. He obtained approximately 20 major assembly drawings by personally visiting the National Archives and Records Administration in Washington, DC. Bill reviewed over 50 microfilm reels and made around 2,500 scans. He later searched for and found about 30 more drawings. Bill contributed over 2,000 hours of time researching, collecting, and making available these O3U-3 drawings. Volunteer archivist Bill Spidle agreed to do the research and find the drawings necessary to build the airplane. Bill gathered 1,600 + drawings from the VAHF microfilm library. He obtained approximately 20 major assembly drawings by personally visiting the National Archives and Records Administration in Washington, DC. Bill reviewed over 50 microfilm reels and made around 2,500 scans. He later searched for and found about 30 more drawings. Bill contributed over 2,000 hours of time researching, collecting, and making available these O3U-3 drawings.

Drawing Formatting and Clean-Up

Many of the drawings obtained from microfilm scans are fourth or fifth generation reproductions. Text and dimensions on these were barely readable. These drawings were "cleaned-up" by Adam Galan using Photoshop™ and PhotoScape X™ computer software, making text, dimensions, and drawing details readable. Large format paper copies were obtained for all of the drawings.

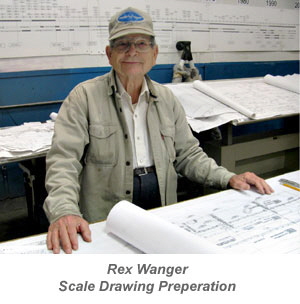

Scale Drawings for Part Fabrication

The VAHF shop workers needed full-scale or at least scale drawings so that they could fabricate O3U-3 parts. These drawings were produced by retired Vought structural design engineers. Carl Klaprott did this work from project start until the work shutdown in late 2013. Carl was assisted in this work by Dave Morse. Carl passed away in June, 2015. When the project was restarted in Building 23 in June, 2015 the scale drawings for the shop were prepared by Rex Wenger until fabrication was completed. The VAHF shop workers needed full-scale or at least scale drawings so that they could fabricate O3U-3 parts. These drawings were produced by retired Vought structural design engineers. Carl Klaprott did this work from project start until the work shutdown in late 2013. Carl was assisted in this work by Dave Morse. Carl passed away in June, 2015. When the project was restarted in Building 23 in June, 2015 the scale drawings for the shop were prepared by Rex Wenger until fabrication was completed.

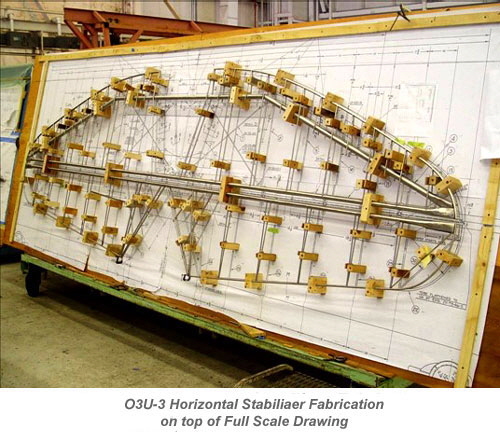

Full scale drawings were prepared for components such as the horizontal stabilizer, elevators, rudders, and ailerons. For these components, the drawings were attached to a sheet of plywood and this became the fabrication tool. The component was constructed on top of the drawing, as shown in the photo of the horizontal stabilizer and elevator below.

Scale flat pattern layout drawings were prepared for the aluminum fuselage skin panels that cover the forward fuselage and cockpit area.

Full scale drawings were prepared for upper and lower wing ribs and the OML outline of the ribs were digitized. This digital information was then used by an outside shop to NC cut all of the wing ribs. The wings are constant chord, so all ribs in a wing have the same contour except for three outboard and two inboard ribs. Most fabricated parts for O3U-3 construction required a scale drawing, so hundreds of drawings were made.

Page 2 of 6

|