|

|||||||

|

Radiation The source of energy for SLAM propulsion was to be a nuclear fission reactor operating at a power level of 600 Megawatts. The reactor was not to have radiation shielding for the fission products of neutrons and gamma rays. As a result, the neutron flux was calculated to vary from 9 x 1017 N/CM2 in the aft section to 7 x 1014 N/CM2 in the nose. Gamma ray energy was expected to be 4 x 1011 MEV in the aft section and 1.2 x 108MEV in the electronics compartment. This required careful selection of materials which could survive not only the high temperatures but also the high radiation levels. The study program investigated all missile subsystems. Some very sensitive ones required a feasible amount of local shielding. The result of the investigations led to the conclusion that missile subsystems were available or could be made available for the SLAM application. Flight testing of the missile was planned to be conducted over the northwest Pacific ocean with termination in deep ocean waters in the neighborhood where atmospheric testing of nuclear weapons had taken place. Reactor

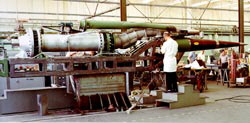

Diameter----------------------57.25 in. The fuel elements for the test reactors were made of the high-temperature ceramic beryllium oxide (BO). This was mixed with enriched uranium di-oxide (UO2) in a homogeneous mixture with a small amount of zirconium di-oxide (ZrO2) for stabilization. This mixture in a plastic mass was extruded by the Coors Porcelain Company under high pressure and then sintered to near theoretical minimum density. Each fuel element was a hollow hexagonal tube approximately 4 inches long, 0.3 inches across flats, and had an inside diameter of 0.227 inches. These were stacked end to end to provide the 50.7 inch length of heated air passage. There were 27,000 of these heated airflow channels and 465,000 individual fuel elements. The design with these small unattached pieces was such that the problems of thermal stress in ceramics was minimized. Two reactor tests were conducted to verify feasibility. Tory II-A was a scaled-down test which was conducted in mid-1961 and operated at design conditions on October 5, 1961. Tory II-C was a full-scale reactor test for a period of 292 seconds which was the limit of the air supply from the storage facility. That facility stored 1.2 million pounds of air which had to be preheated to 943 degrees Fahrenheit and supplied at a pressure of 316 psi to simulate ramjet inlet diffuser conditions. Tests were conducted at Jackass Flats in The Nevada Test Station by Lawrence Radiation Laboratory. These tests demonstrated the feasibility of the nuclear power-plant for the SLAM weapon system. SLAM Description: Airframe |

The reactor development work for nuclear propulsion systems was started by the NEPA Project and specific development for nuclear ramjet application at the Aircraft Nuclear Propulsion Department of the General Electric Company. As the ramjet program gained in importance, it was moved to the Lawrence Radiation Laboratory (LRL) of the University of California in January 1957. LRL’s working with Chance Vought for missile propulsion requirements resulted in the following nuclear reactor characteristics for the SLAM weapon system:

The reactor development work for nuclear propulsion systems was started by the NEPA Project and specific development for nuclear ramjet application at the Aircraft Nuclear Propulsion Department of the General Electric Company. As the ramjet program gained in importance, it was moved to the Lawrence Radiation Laboratory (LRL) of the University of California in January 1957. LRL’s working with Chance Vought for missile propulsion requirements resulted in the following nuclear reactor characteristics for the SLAM weapon system: